Maximum allowable pressure is calculated with the barlow s formula for a53 grade b seamless and welded standard steel pipe with yield strength 35000 psi and design factor 0 7.

Schedule 80 aluminum pipe pressure rating.

It is seamless so it has a smooth interior for unrestricted flow.

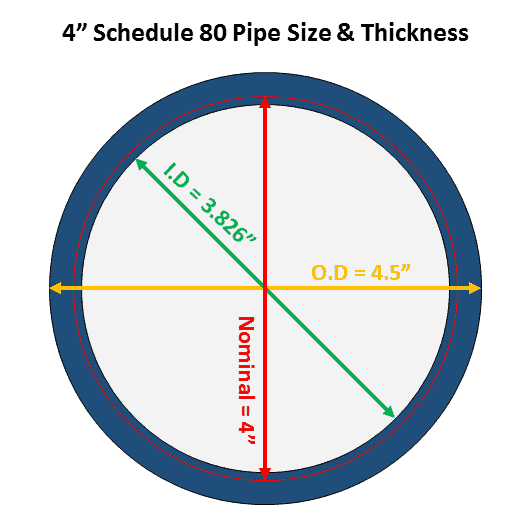

Schedule 40 and schedule 80 refer to the thickness of the walls of pipes.

Fully threaded pipe is also known as a close nipple.

Also known as schedule 40 pipe it is for use in low pressure applications.

Api 5l carbon steel pipe and a 106 a 53 a333 a334.

Pressure ratings pressure ratings of pipes and tubes and their fittings carbon steel stainless steel plastic copper and more.

Larger schedule 80 pipe that is used for internal installation ranges from 2 inches to 3 1 2 inches in diameter.

Aluminum pipe calculator solving for pressure rating given allowable stress.

It is seamless which provides a smooth interior for unrestricted flow.

In codes like asme b31 3 modified versions of the barlow s formula like the boardman formula and the lame formula.

Made of aluminum this pipe is lightweight with good corrosion resistance.

For technical drawings and 3 d models click on a part number.

Minimum tensile strength 60 ksi 60000 psi.

Aluminum pipe equations formulas design calculator fluid mechanics hydraulics.

Inch psi 145 0 megapascals mpa ksi 0 145 megapascals mpa kilograms mm kgf mm 0 10197 megapascals mpa bar 10 00 megapascals mpa kilopascals kpa 1000 limitation of liability.

Allowable stress used in the barlow s formula is calculated as 35000 psi 0 7 24500 psi note.

Also known as schedule 80 this pipe has extra thick walls to handle high pressure applications.

Pipes 3 1 2 inches in diameter have a service rating of 990 psi and a burst pressure of 7 950 psi.

To convert to multiply by megapascals mpa pounds sq.

Pipe is aluminum which is lightweight with good corrosion resistance.

Solving for pressure rating.

This table defines the maximum pressure rating for the specified industry standard pipes schedule 160 schedule 40 and schedule 80.

Schedule is the standard of wall thickness that has been adopted by the american national standards institute.

It is threaded on each end to the center.

As per the institute the thickness of wall pipes varies from schedule 10 schedule 40 schedule 80 and schedule 160.

For technical drawings and 3 d models click on a part number.

Fully threaded pipe is also known as a close nipple.

It has most of the good qualities of aluminum.

Ansi b16 5 steel pipe flanges pressure and temperature ratings group 1 2 pressure psig and temperature ratings for steel pipe flanges and.

It offers a range of good mechanical properties and good corrosion resistance.

It is threaded on each end to the center.

Under most cases s 7500 pound inch 2 for aluminum.

A 2 inch pipe is rated for 920 psi of continuous service pressure and will burst at 7 340 psi.

Pipes with schedule 40 come with standard weight and pipes with schedule.

Maximum pressure ratings for pipes per.

Aluminum tubing allowable pressure allowable pressure for aluminum tubes.

Seamless aluminum pipe series 6061 t6 schedule 80.

6061 is the least expensive and most versatile of the heat treatable aluminum alloys.